The smart catalogue is now at your fingertips

Protect your colleagues by selecting the right protective apparel.

Select one of the options below to begin your product search using the selector tools.

Our Brands

Tyvek® delivers comfortable and durable protective garments that protect against a wide range of chemical threats and hazards. From the cleanroom to a hazardous cleanup, Tyvek® provides the right PPE for the job.

Not all deadly threats come in the form of fires or weapons. For comprehensive protection against low levels of dangerous chemicals, to toxic gases and biological hazards, industrial workers rely on garments made of DuPont™ Tychem®.

ProShield® garments can help protect against non-hazardous dry particles and light liquid splash applications typically found in industrial situations.

Tyvek® IsoClean® garments have a long history of use in cleanrooms due to their excellent barrier to particles, microorganisms and non-hazardous liquids. They offer an ideal balance of protection, durability, comfort and contamination control.

Our Featured Products

DuPont provides industry-leading protective options designed to keep you safe on the job. From FR apparel to protective gloves and coveralls, DuPont provides unparalleled protection from the neck down.

- Tyvek® 500 Xpert

Applications for Tyvek® 500 Xpert garments include those found in pharmaceutical handling, chemical processing, the oil and gas industry, general maintenance and operations, automatic spray painting and many others.

- Tychem® 6000 AL

Tychem® 6000 AL garments are designed to help keep workers safe and focused when carrying out critical tasks in industries like Pharmaceutics, Chemicals and others.

- Tyvek® IsoClean® 193 coveralls

Garments and accessories made of clean-processed and sterile Tyvek® IsoClean® are typically used in cleanrooms within the biotech, pharmaceutical, medical device manufacturing, food processing, cosmetics industry as well as in other critical or controlled environments.

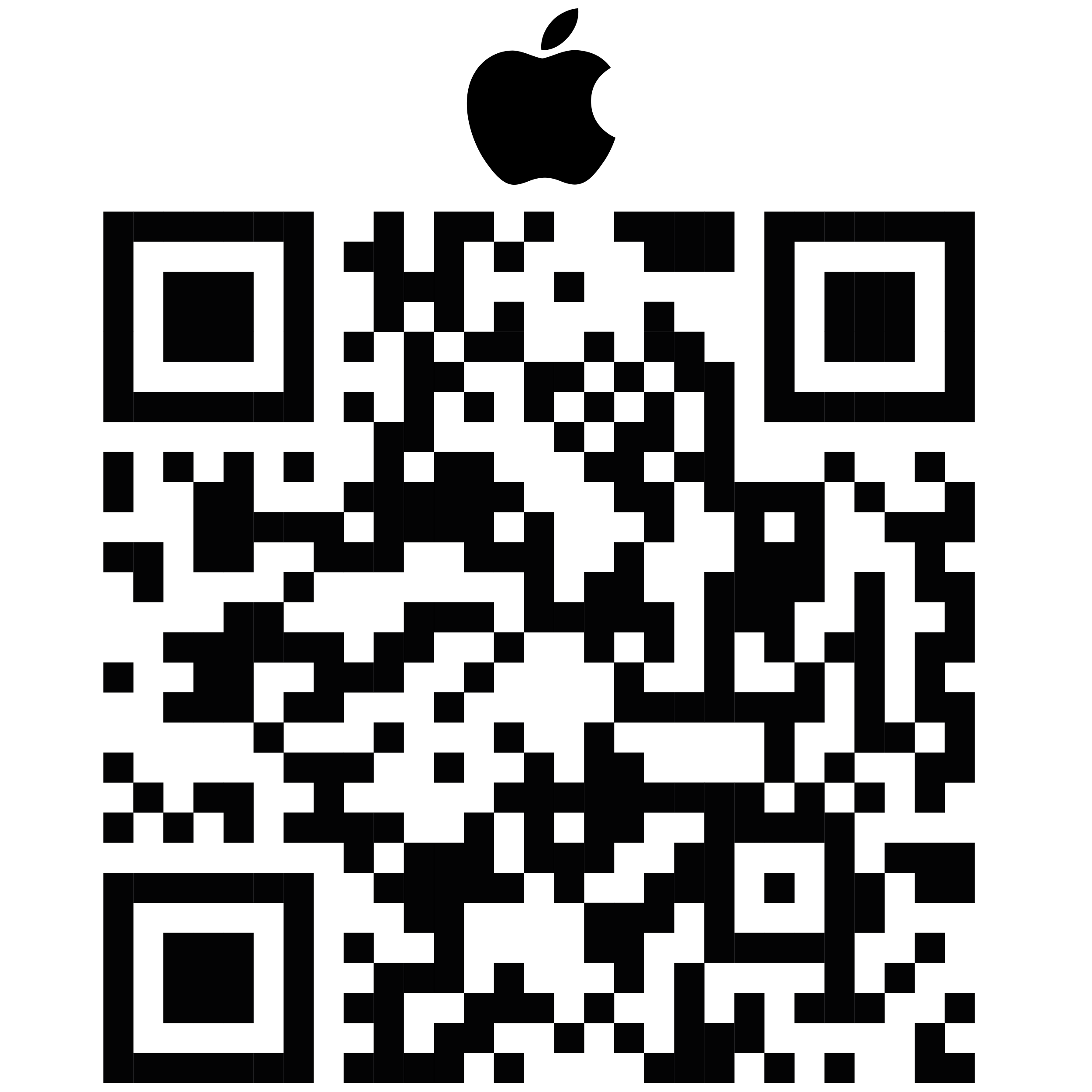

Get the free SafeSPEC™ mobile app